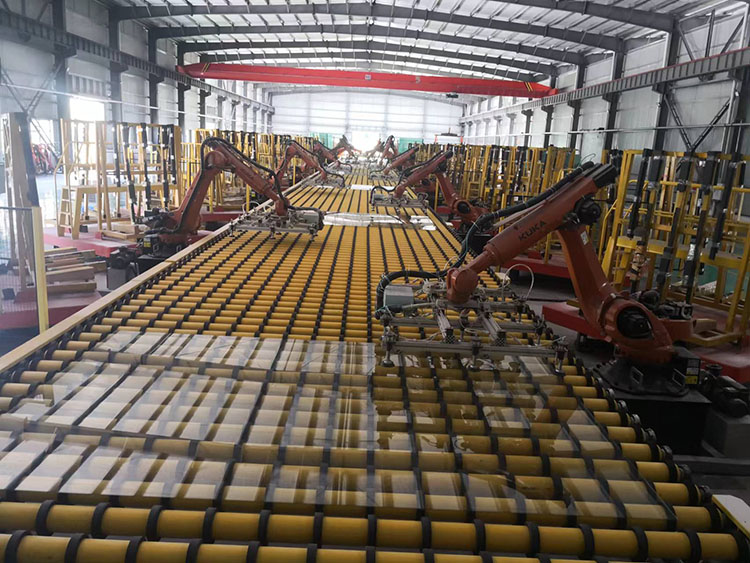

Cold end system

The cold end roller system operates smoothly, reduces noise, has a long lifespan, and is easy to maintain.

Emergency drop device

Blow air cleaning device

Online glass defect detection device, which detects glass defects such as bubbles and stones, and optimizes cutting by connecting with the cutting system.

Manual quality inspection room, manually combined with online glass defect detection device detection data for defect correction, used for optimizing cutting.

Length measurement and communication device

Fully automatic slitting machine, automatic positioning, positioning accuracy ± 0.4 mm

High precision cross cutting machine, which can automatically select cutting specifications based on the location of defects.

Horizontal breaking device, pneumatically driven, can achieve online breaking of glass.

The narrow strip auxiliary breaking and rapid drop device can be used to optimize the cutting of glass breaking and glass direction with a horizontal drawing range of 300 to 500mm.

The acceleration separation roller table is placed between the traction section roller table and the high-speed section roller table, and adopts two-stage acceleration.

The edge breaking roller table and edge breaking device are used to break off the natural edges of glass panels.

The longitudinal breaking and splitting device adopts a pneumatic device for the lifting and lowering of the longitudinal breaking wheel, achieving the longitudinal breaking and splitting of the glass.

The mainline keyboard type selective drop device can be combined according to the specifications of the glass to achieve selective dropping.

Glass powder spraying machine, glass isolation packaging and mold prevention, can be set with selective powder spraying.

Stacking manipulator, according to the setting, achieves grading, specification, or horizontal stacking of left and right pieces on two turntables.