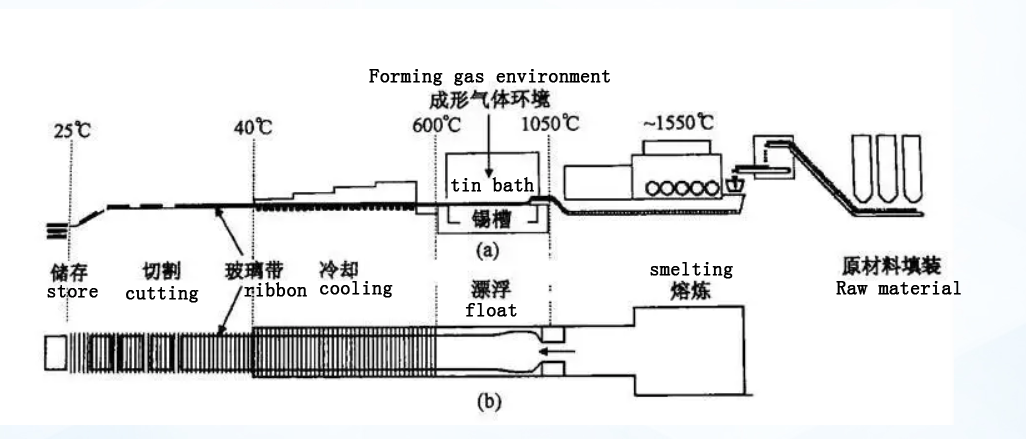

Float glass: under the melting state, the glass liquid continuously flows out from the furnace and floats on the metal tin liquid level filled with protective gas. Under the combined action of its own gravity, surface tension, edge roller and transmission tension, it forms a glass belt with uniform thickness, parallel surface, flat and polished, and then annealing, cooling and cutting is an efficient and high-quality method for manufacturing flat glass. Its glass products have the characteristics of good surface flatness, uniform thickness, no water ripple, and no deformation of the original glass plate during deep processing. The glass production line has the advantages of low energy consumption per unit product, long continuous operation cycle, easy to realize the mechanization and automation of the production line, and high labor productivity.

High-end float glass mainly refers to the high quality, high performance varieties of high quality float glass with ultra-white, ultra-thick, body tinting, online coating and other functions.

Under the leadership of Dr. Jiang Hong, our company has a high-quality, high-efficiency and technologically advanced design team. The core technicians of the team come from the professional and technical team of the three international float process "Luoyang Float". They have been engaged in the design and production of float glass for more than 30 years. They have rich design experience and production technology knowledge. They have pioneered and introduced a variety of leading technologies in the design of glass production lines, and have a high technical reputation in the same industry.

He has presided over the design and construction of many float glass production lines with different tonnage at home and abroad, as well as the renovation of existing line transformation, and the production technical services such as body tinting and online coating. It can provide a full set of design, construction and installation of various float glass production lines with daily melting capacity of 50T/D to 1200T/D, as well as production and technical services such as existing line transformation and technical upgrading.